By Andrew Dawson, Managing Director at Cognizance Processing

The COVID-19 pandemic has in this time of unprecedented demand for essential goods revealed many vulnerabilities in supply chains, logistics and fulfilment operations. And unlike natural disasters that involve the physical destruction of buildings and infrastructure, the pandemic continues to threaten those businesses that aren’t adapting quickly enough to meet bulk buying and unusual demand.

Increased demand for e-commerce goods, particularly in levels 4 and 5 of the country’s national lockdown, put massive pressure on an already strained supply chain. This created a demand for manufacturers, distributors and suppliers to implement additional support for individual picking and packing, shipping of goods and last-mile delivery.

Now in an economy that is gradually starting to return to some of form of normalcy, business decision makers are faced with the reality that they will have to rethink the way their logistics and supply chain backbones’ function. This is to sufficiently meet demand for essential goods such as sanitisers, masks and other PPE (personal protection equipment) and high-demand products such as home office equipment.

Additionally, manufacturers, distributor and retailers will have to stay one step ahead of supply and demand requirements by optimising data, implementing intelligent analytics and ensuring they aren’t caught off guard with too little or too much stock.

Speed to market is critical and similarly predicting potential upswing in product demand. Organisations must look at the entire value chain, addressing areas that need smoothing and ensuring they remain competitive particularly as more players emerge out of seemingly nowhere.

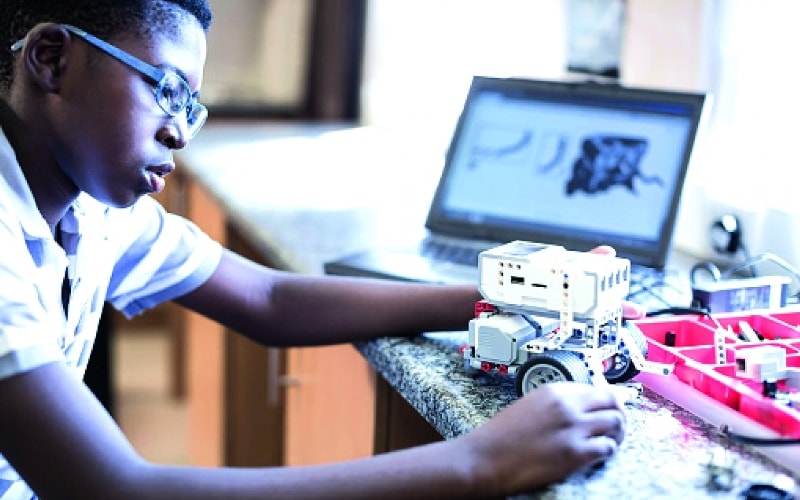

In the “new normal”, organisations must also start considering automation, robotics and the establishment of a truly mobile workforce that can continue to work optimally despite their physical location.

Interestingly, even before the beginning of the pandemic, organisations had already started implementing robotics, automated material handling equipment, artificial intelligence (AI), voice, and other advanced technologies into their warehouses and distribution centres.

These solutions offer an efficient solution to manage high-velocity operations with limited labour resources while meeting the ever-changing demands generated by digital commerce.

And now, more than ever, automation, robotics and AI have emerged as an important tool to automate and digitally transform companies, strengthening their efforts to stay competitive and importantly meet consumer demand in truly volatile marketplace.

In the supply chain, automation, digital connection and edge technologies such as AI and robotics are integrated, working together to achieve the speed, efficiency and resiliency while keep the lines of supply moving and open both in times of normalcy and crisis.

In a recent survey by research group IDC, nearly 28% of respondents ranked “improving supply chain resiliency/responsiveness” as a top concern driving strategic change in their supply chains. This number will undoubtedly become higher in coming months.

Lastly, without becoming too SciFi, the acceleration of robotics and automation might even give way to “dark warehouses” which will operate 100% autonomously, allowing organisations to mobilise their employees towards other critical operations that can’t be digitised.